Our Story

Predictive Maintenance Diagnostics (PMD) is a spin-off company of Stultz Electric Works; a family owned motor repair shop owned and operated by the Stultz family from 1907 to 2003. For several years PMD was a division of Stultz Electric Works used primarily to complement the motor repair services at Stultz. In September of 1995 PMD was separately incorporated and has operated as an independent S Corporation ever since. Although wife Cynthia is the major shareholder and president of PMD, Jim Stultz and his son David are the ones doing the data collection and diagnostics analysis.

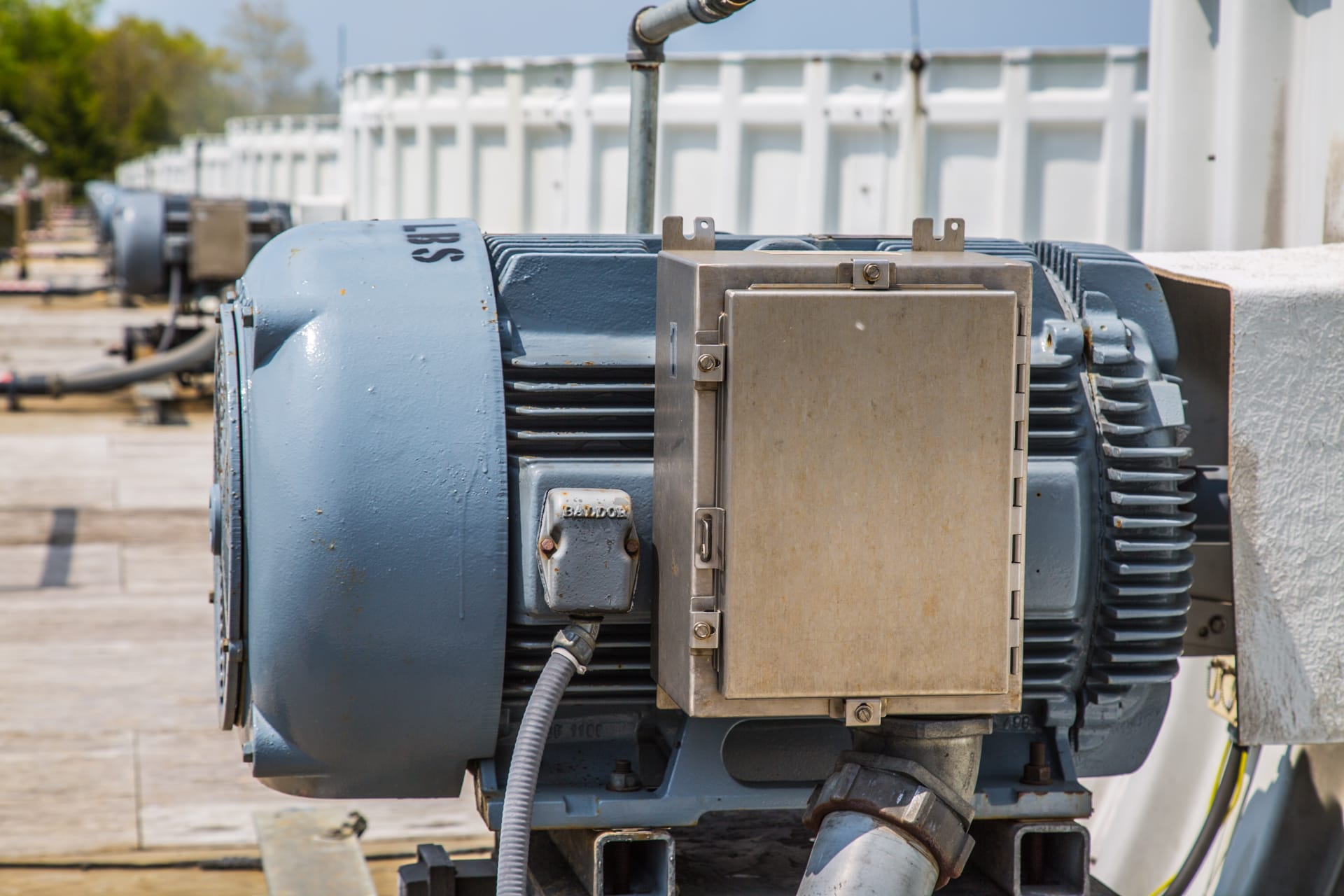

While working in the repair industry for over 35 years, Jim witnessed firsthand the catastrophic failures that resulted from lack of maintenance or delayed repairs. Had action been taken early on, repairs would have been minimal, downtime could have been reduced and costs of those repairs would have been far less than what ultimately resulted. Now that Jim is no longer affiliated with any repair shop, he can operate as an independent technician in helping customers diagnose potential problems without bias to any repair shop. If a newly repaired piece of equipment develops a problem after being commissioned into service, Jim can assist customers without any bias or prejudice should faulty “repairs” be the cause.

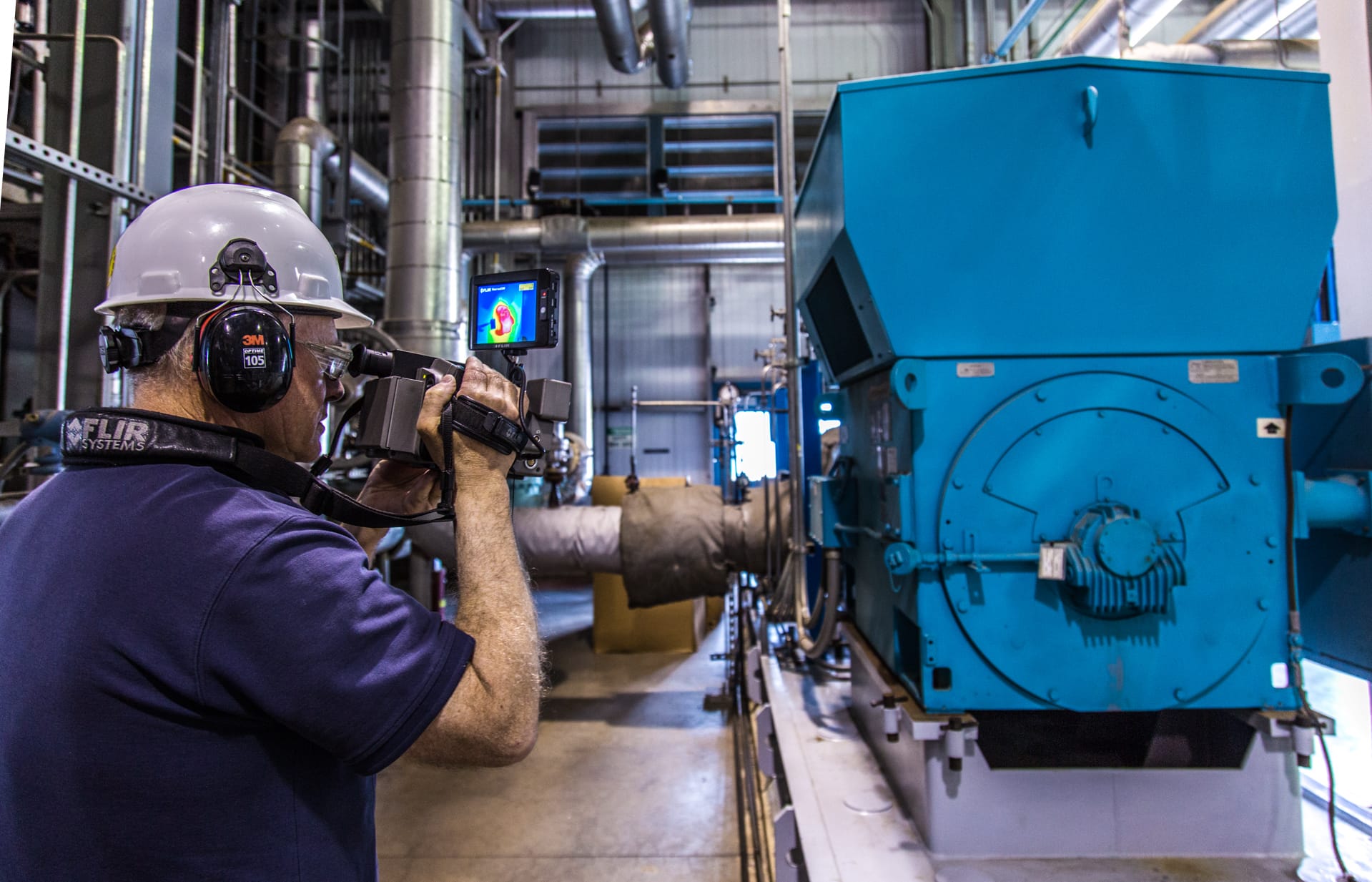

PMD does exactly what the name implies; it “predicts” required “maintenance” using state of the art “diagnostics” equipment via data collection on rotating equipment and associated electrical controls. It is the early warning of equipment degradation that allows for the scheduling of maintenance work before catastrophic failures occur. PMD uses several specific diagnostics methods to routinely collect data on equipment to determine vibration conditions and thermal profiles of the electrical components. This data is then used in order to diagnose current equipment conditions while comparing current conditions to the equipment’s historical condition. Historical data is often used for comparison purposes from month to month, year to year or for comparison of similar types or equipment or “sister” machines.

Jim and David use non-invasive diagnostics equipment for vibration analysis, infrared scanning, ultrasound listening, on site dynamic balancing and laser alignment. The team has a proven track record in identifying problems, or potential problems before they become critical. The collection of diagnostics data coupled with years of hands on experience provides customers with an unbeatable analysis advantage. Not only can they provide diagnostics of potential problems, but are able to draw on experience in recommending causes as well as solutions to the problems. The team doesn’t necessarily perform repairs; however, they quite often can walk customers through the necessary steps in isolating problems and repairing of the equipment.